Product

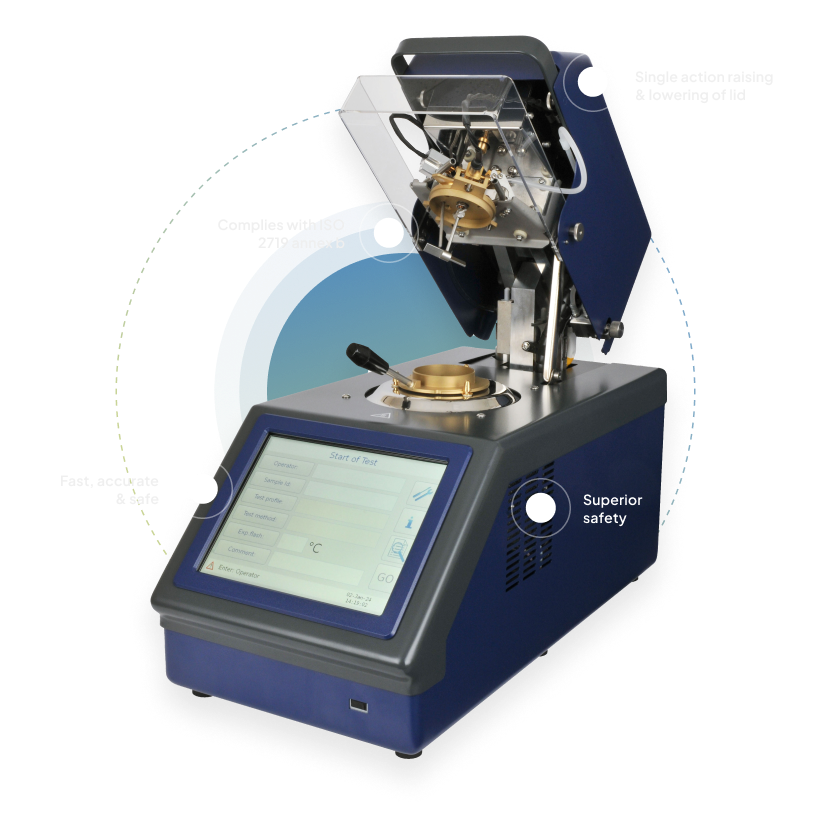

H₂S Analyser with Vapour Phase Processor - SA4000-4

The H2S Analyser with Vapour Phase Processor (VPP) is a compact bench-top instrument, used to measure the total hydrogen sulphide (H2S) content of fuel oils, such as marine residual fuels, distillates and petroleum blend stocks. The H2S Analyser can measure H2S concentrations from 0 to 250 mg/kg (ppm) in the liquid phase.

Designed with an integrated VPP, components such as toluene, xylene, thiols (mercaptans) and alkyl sulphides are removed to ensure the accuracy of results.

An analytical balance can be connected to the H2S Analyser which reads the data from the balance and automatically calculates the sample mass, saving time and eliminating the risk of data entry errors.

Other enhanced functionality features include real-time graphical display of test progress, custom result reporting and automated gas calibration.

Statistical Quality Control (SQC) software allows analysis of results in accordance with ASTM D6299.

A limit of 2 parts-per-million (2 ppm) in the liquid phase was set by the industry in 2012 under ISO 8217, which made IP 570 Procedure A the referee test for H2S.

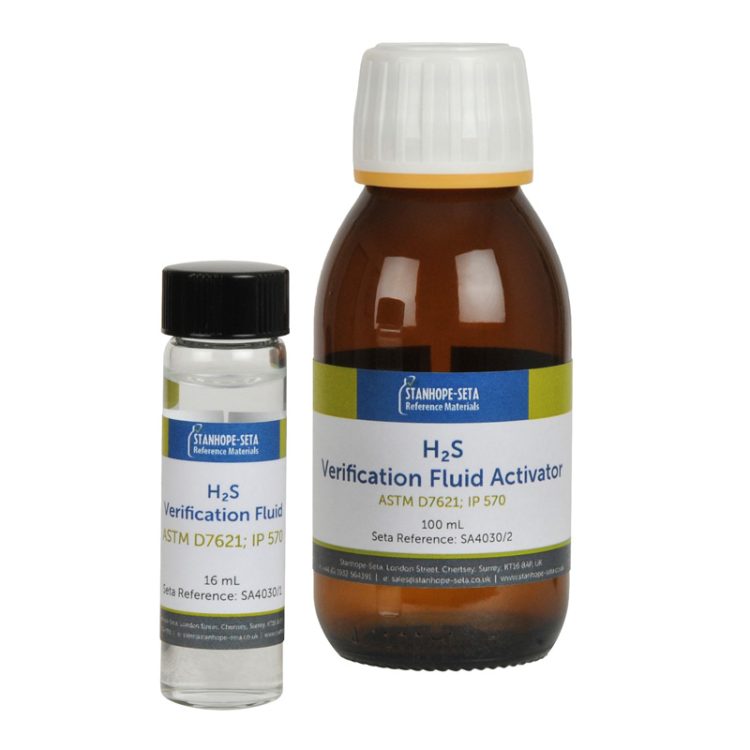

IP 570 includes the use of verification fluids as a recommended practice. Participation within a Proficiency Test Scheme (PT Scheme) is stated as the preferred means to achieve this.

Features

- Measurement range from 0-250 mg/kg H2S

- Built in Vapour Phase Processor

- Non chemical method, no wet chemistry involved

- Small lab bench footprint

- Integral camera to aid sample input

- Custom result reporting and LIMS output

- Weighing balance connectivity and automation

- Statistical Quality Control software

Information

Details

Ease of use:The H2S features a simple user interface with touchscreen display. An integrated camera showing the test vessel aids sample input and ensures the correct amount of sample is used for accurate results.

Cost saving:

Due to the simplicity of test set up and no requirement for analytical preparation by an experienced chemist, low operator time is needed to run a test, helping to reduce labour costs.

The H2S Analyser requires only a small sample volume, helping to reduce cost and waste per test.

As the H2S uses a non-chemical method, no costly or hazardous chemicals are required.

Calibration and verification:

Calibration of the H2S Analyser can be performed in the field, eliminating the costs and time associated with sending the instrument to a service centre.

Service and maintenance:

The rugged design ensures minimal operational maintenance in needed.

Details

| IP 570 | Determination of hydrogen sulfide in fuel oils - Rapid liquid phase extraction method |

|---|---|

| ASTM D7621 | Determination of Hydrogen Sulfide in fuel oil - rapid liquid phase extraction method |

| ISO 8217 | Fuel Standard for marine distillate fuels and for marine residual fuels |

| ISO/PAS 23263 | Petroleum products - Fuels (class F) - Considerations for fuel suppliers and users regarding marine fuel quality in view of the implementation of maximum 0,50% sulfur in 2020 |

Details

| Measurement range | 0-250 mg/kg H2S in the liquid phase (0-250 ppm H2S) |

|---|---|

| Viscosity range | 1-3000 mm2/s at 50C |

| Principle of measurement | Electro-chemical sensor |

| Test duration | 15 minutes |

| Sample size | 1ml, 2ml, 5ml (depending on H2S concentration) |

| Diluent volume | 20ml |

| Results format | Numerical and graphical display |

| Memory | 500,000 result memory. Print via external printer, export to LIMS, USB or QR code |

| Connectivity | RJ45 Ethernet, RS232 Serial or USB |

| Voltage | 100/240 V, 50/60 Hz, auto-sensing universal power supply |

| Size (HxWxD) | 52 cm x 29 cm x 57 cm |

| Weight | 15 kg |

| CCCN Code | Tariff 90268020 |

Methods

Industries

Spares and accessories for H₂S Analyser with Vapour Phase Processor - SA4000-4

H2S Consumables kit (200 tests) - SA4005-4

View accessory

H2S Liquid Trap (pack of 5) - SA4000-009

View accessory

Moisture/Particulate Filters (pack of 50) - SA4000-003

View accessory

H2S Syringes (pack of 200) - SA4000-007

View accessory

H2S Diluent 5 litres - SA4013-0

View accessory

H2S Vapour Phase Processor Cartridge (pack of 100) - SA4017-100

View accessory

Printer Paper (Pack of 20) - 81002-301

View accessoryDownload product profile

To view our full range of products, download our latest Product Profile here.

Want to know more?

View our full range of products, or simply get in contact with us for more information.