Product

SetaFoam Dual Twin Foam Test Baths - 14020-8

These pair of highly transparent water baths are for detecting undesirable foaming characteristics in lubricating oils, which could cause inadequate lubrication, overflow and cavitation.

The instrument comprises a high temperature (normally 93.5 °C) and a low temperature (normally 24 °C) bath, each with the capacity to hold four 1000 ml graduated glass cylinders.

Each bath assembly comprises an inner glass bath contained in a polycarbonate safety vessel, a top mounted thermostir unit.

The bath has integral back-lighting with an opaque reflector which aids sample visibility and foam measurements. In addition, the low temperature bath has a cooling coil for use when the laboratory ambient temperature exceeds the required bath temperature, and two air normalising coils to cool the air emerging from the high temperature bath test cylinders prior to passing to external volume meters.

Features

- Up to two simultaneous tests per bath

- Two pre-heating stations per bath

- Two integral normalising coils

- Local verification of the stones possible using the verification kit

Information

Details

The baths incorporates the Thermostir (15160-0) unit, which provides precision temperature control to within ±0.5 °C across a temperature range of ambient to 100 °C. It has an easy to use rotary dial and two function keys for quick temperature setting and menu navigation. The Thermostir is protected against over-heating by an independent over-temperature cut-out which is user adjustable via the over-temperature dial.

Easy to remove stoppers ensure air tight seals and central location of the diffusers. All air connections are via quick release connectors, and the diffuser tubes can be used with either Mott diffusers or Norton Stones.

Notes:

A DigiFlow Mass Flowmeter (14012-0) or Dual Glass Flowmeter (14011-2) is required per cylinder for testing, these are supplied separately and should be selected when ordering.

Stanhope-Seta recommends the use of the Pump and Accessory Kit (14019-2), supplied complete with pressure relief valve and regulator. A Drying Tower (14015-2) is also available as an accessory. A clip to attach the drying tower can be mounted on the side of the flowmeter mounting bracket.

Supplied with;

Four graduated 1000 ml cylinders and stoppers

Interconnection tubing and junctions

Mains leads

Instruction manual

Details

| ISO 6247 | Determination of foaming characteristics of lubricating oils |

|---|---|

| IP 146 | Determination of foaming characteristics of lubricating oils |

| ASTM D892 | Test method for foaming characteristics of lubricating oils |

Details

| Outer | Polycarbonate |

|---|---|

| Inner | 28 litre, borosilicate glass |

| No of Baths | 2 |

| No of Cylinders per bath | 4 (2 per bath supplied) |

| Cylinders | 1000 ml, borosilicate glass, graduated |

| Diffuser | Mott or Norton Stone |

| Flowmeters | 2 per bath, 94 ±5 ml/min |

| Control Units | Thermostir, 1 per bath |

| Temperature range | Ambient to 100 °C ±0.5 °C |

| Supply Voltage | 110/120 V, 60 Hz or 220/240 V, 50/60 Hz |

| Power | 3kW |

| Size (HxWxD) | 70 x 48 x 40 cm |

| Weight | 50 kg |

| CCCN Code | Tariff 90268020 |

Methods

Industries

Spares and accessories for SetaFoam Dual Twin Foam Test Baths - 14020-8

Cylindrical Metal Diffuser and Tube with Works Certificate - 14023-0

View accessory

Digital Stopwatch - 22750-3

View accessory

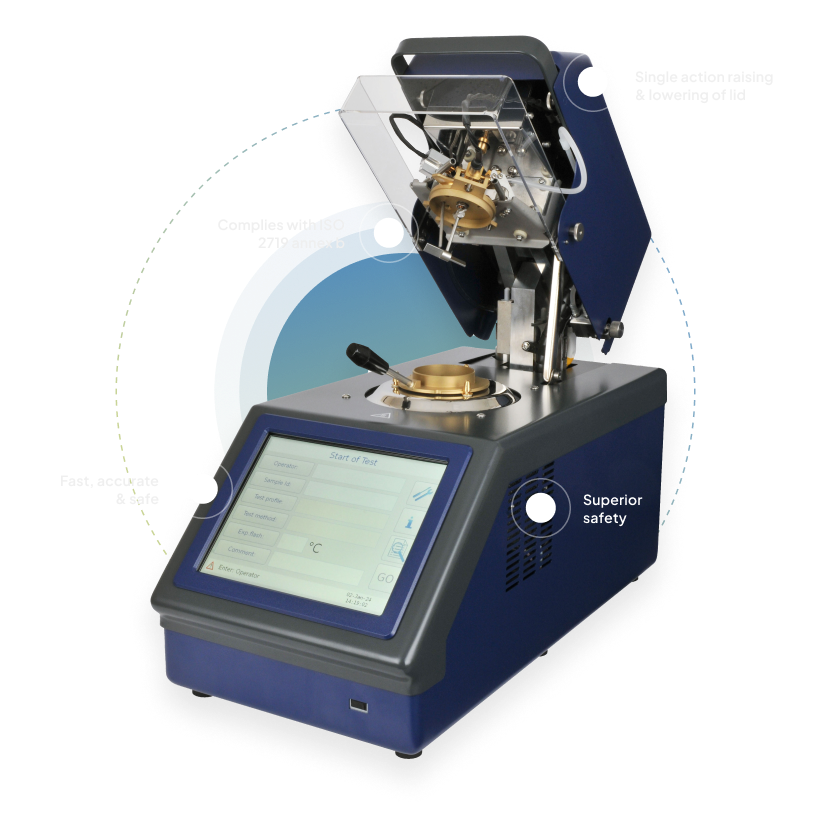

DigiFlow Mass Flowmeter - 14012-0

View accessory

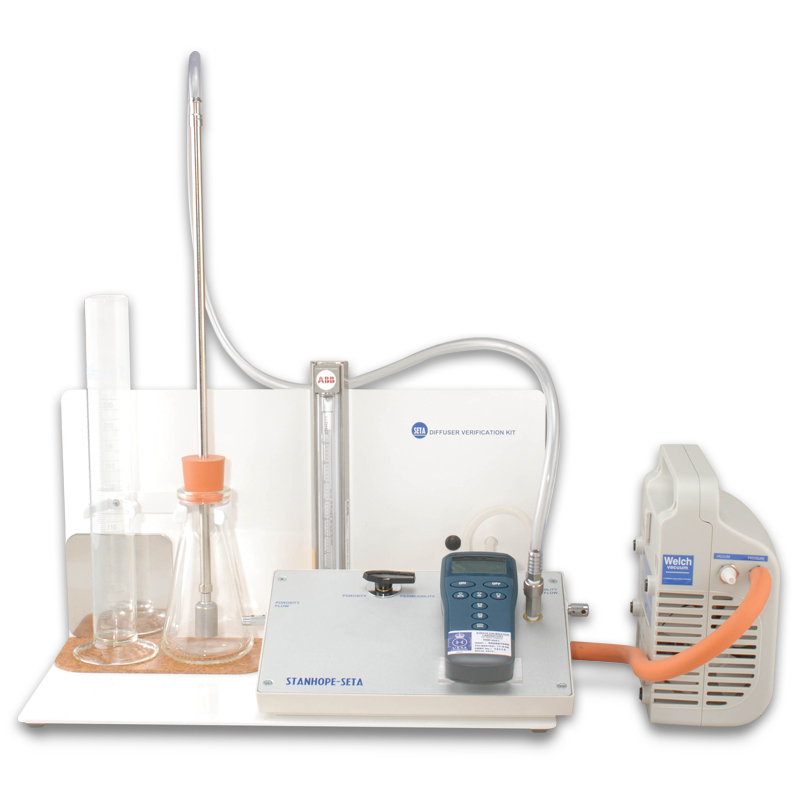

Vacuum Pump and Accessory Kit - 14019-2

View accessory

Dual Glass Flowmeter - 14011-2

View accessory

Drying Tower for ASTM D892 - 14015-2

View accessory

Rack for Foam Cylinder - 14029-0

View accessory

Spherical Diffuser and Tube with Works Certificate - 14021-0

View accessory

Water Purifier - 15650-0

View accessory

Centering Washer (Pack of 5) - 14038-0

View accessory

Centering Washer (Pack of 5) - 14037-0

View accessory

Thermometer ASTMS12C: Low Haz with Certificate of Conformity - ASTMS12CX

View accessory

Thermometer Digital: Precision -199 to 199 °C - 51000-0

View accessory

Temperature Indicator and Probe - 14026-0

View accessoryDownload product profile

To view our full range of products, download our latest Product Profile here.

Want to know more?

View our full range of products, or simply get in contact with us for more information.