Product

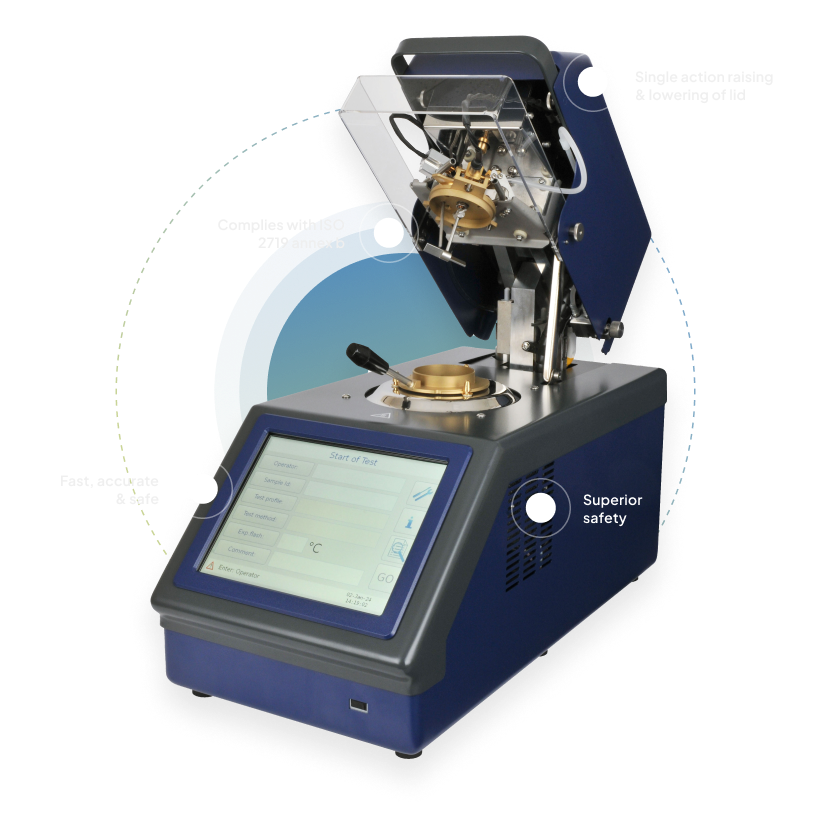

Herschel Emulsifier - 96700-2

The Herschel Emulsifier is a compact and efficient benchtop instrument designed to measure the ability of petroleum oils and synthetic fluids to separate from water.

The instrument incorporates 4 test stirrers, with independent control and motorised raising and lowering. Samples can be tested simultaneously or individually to suit laboratory requirements.

Test cylinders are located in a temperature controlled bath with an adjustable set point of either 54 or 82 °C, in accordance with ASTM and ISO test methods. A large LCD touch screen display is used to initiate test and provides automated sequencing with an audible and visual reminder at each recording interval.

Features

- Multiple operator safety features

- Intermediate scraping position

- Integrated timing

- No removal of the paddles required

- Guaranteed paddle rotation speed

- Non-reflective enhanced LED lighting

- Large viewing window

- Small footprint

Information

Details

Operator Safety- Obstruction override if paddles are placed under any resistant load

- Duplex protective viewing glass

- Automatic high temperature cut out

- Overflow prevention

- Automatic low-level liquid trip

- Abort button for emergency all stop

Ease of Use

- Fully automated paddle movement with motorised raising and lowering

- Easy sample handling without removing the stirrer paddle

- Self-centering collet to ensure concentricity within 1 mm

- Positioning within 6mm from the bottom of the cylinder automatically achieved

- Large LCD touch screen display

Precision and Accuracy

- Non-reflective enhanced LED lighting for improved measurement precision

- Post stirring, intermediate scraping position ensure accurate readings

- Guaranteed paddle rotation speed, regardless of viscosity

- Large viewing window

Enhanced Test Throughout

- 4 independently controlled test stations reduce waiting time

- Rapid bath heat up time

Details

| ASTM D1401 | Standard test method for water separability of petroleum oils and synthetic fluids |

|---|---|

| ISO 6614 | Water Separability of Petroleum Oils and Synthetic Fluids |

| IP 412 | Petroleum products - Determination of water separability of petroleum oils and synthetic fluids |

Details

| Bath Volume | 5 litres |

|---|---|

| Bath Liquid | Water or white oil |

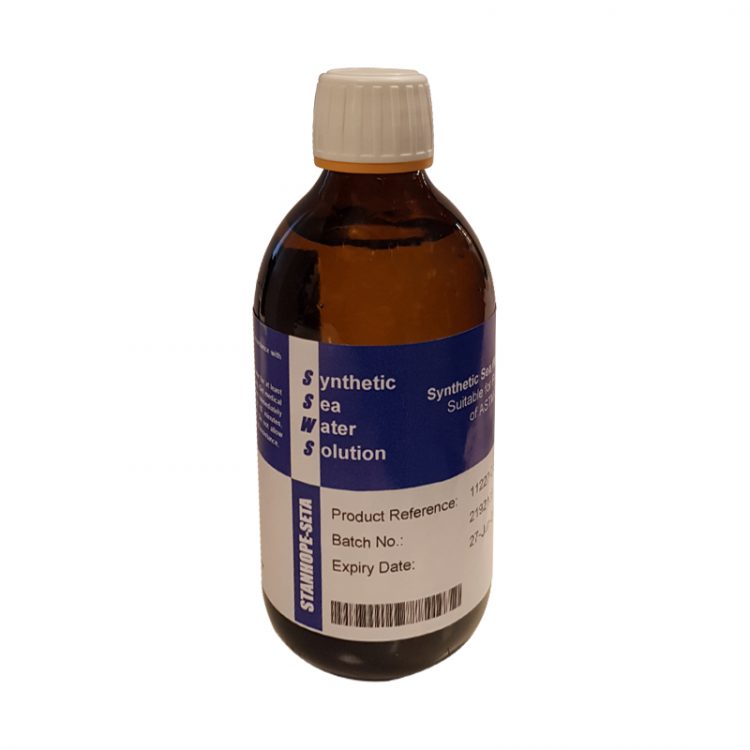

| Sample Size | 40ml oil, 40ml distilled water, 1% sodium chloride solution or synthetic seawater |

| Temperature Eange | 54 °C and 82 °C |

| Bath Temperature Stability | ±1 °C |

| Stirrer Speed | 1500 ± 15 rpm |

| Voltage | 110/240 V, 50/60 Hz, Autosensing Universal PSU |

| Display | LCD touchscreen |

| Size (HxWxD) | 89 cm x 45 cm x 45 cm |

| Weight | 49.5 kg |

| CCCN Code | Tariff 90318080 |

Methods

Industries

Spares and accessories for Herschel Emulsifier - 96700-2

Download product profile

To view our full range of products, download our latest Product Profile here.

Want to know more?

View our full range of products, or simply get in contact with us for more information.