Product

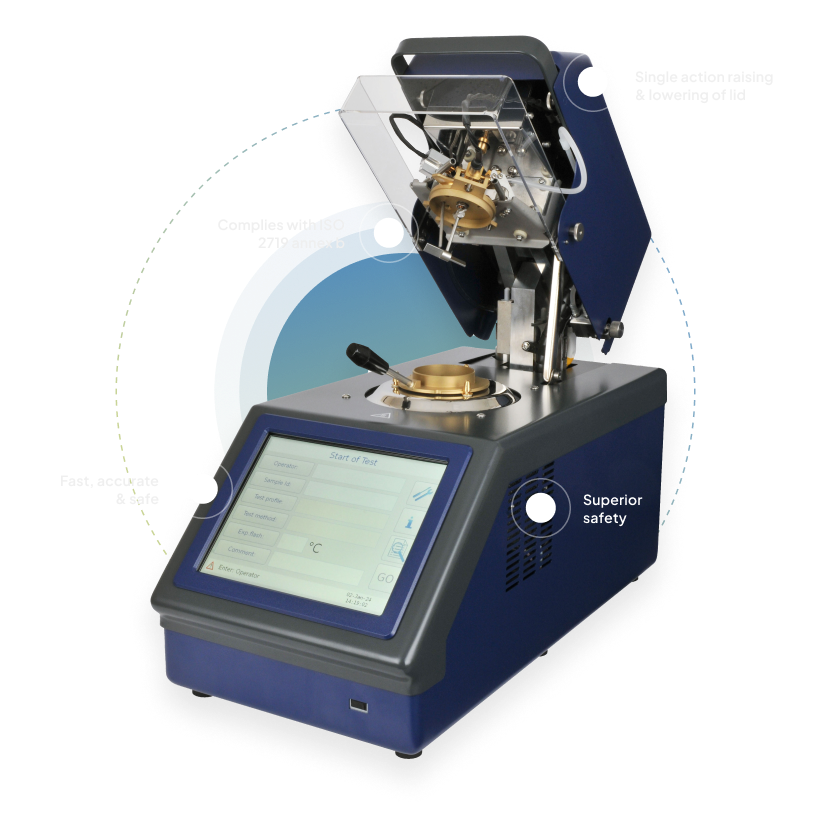

Water Separation Instrument- WSI Analyser - SA9000-0

The Water Separation Instrument (WSI) is a fully automatic and compact bench top / portable instrument. The instrument measures how effectively a fuel sample releases entrained and emulsified water when pumped through a water coalescing filter. The measured water separation index clearly displays at the end of the test.

The WSI is operated via a simple user interface with touch screen display. The fully automated test means minimal operator knowledge is required; little to no training is needed to use the instrument. The automatic test sequence and consistent sample handling also ensures test repeatability and reproducibility.

Due to the simplicity of set up and automation, low operator time is required, which reduces labour costs. The WSI has inexpensive consumables and just one low cost filter per test; this allows additional savings and reduced waste per test. Additionally, easy on site calibration eliminates the time and costs associated with sending an instrument to a service centre.

The WSI’s internal data storage allows access to past results which can be exported by USB connection to PC for further analysis.

- Defence Standard 91-091 now includes WSI - ASTM D8073, IP624 as an alternative test for Water Separation at point of manufacture

- JIG Bulletin 150 issued – The preferred method for testing fuels containing a Static Dissipator Additive [SDA] downstream of the Point of Manufacture is now WSI – ASTM D8073, IP624

- ASTM D1655 allows the use of WSI – ASTM D8073 as downstream test for fuels

Learn more about why measuring water separation in fuel is so important

Features

- Fully automated test procedure

- Suitable for untrained operators

- Automated sample mixing for increased accuracy

- Rapid test, no warm up time

- Internal data storage and USB output

- Substantial consumable cost and waste saving

- Field calibration, no down time

Information

Details

Water Separation TestBefore each test the Water Separation Instrument flushes the test specimen, primes the instrument and primes the filter. When the test starts the unit pumps dyed water into the test specimen and emulsifies the solution with the sonicator. After a specific time the emulsion is pumped through a particulate filter, the dye detector and into the waste container to provide a reference value. Once a reference value is acquired, the emulsion is diverted through a filter cartridge to remove the dyed water before it passes through the detector again and a new set of readings are taken. The water separation index is calculated from the reference value and subsequent readings. Results display on the screen.

Test results are stored on the WSI or you can save the results onto a computer.

WSI Filter cartridges use API/EI 1581 5th edition filter material which is less sensitive to weak surfactants and is less affected by SDA, eliminating uncertainty over static dissipater additives, but is responsive to the presence of ester based additives.

Details

| ASTM D1655 | Standard Specification for Aviation Turbine Fuels |

|---|---|

| DEF STAN 91-091 | Aviaton Fuel Specification |

| ASTM D8073 | Procedure to rate the ability of aviation turbine fuels to release entrained and emulsified water when passed through a water coalescing filter. |

| IP 624 | Procedure to rate the ability of aviation turbine fuels to release entrained and emulsified water when passed through a water coalescing filter. |

| ATA 103 | Standard for Jet Fuel Quality Control at Airports |

| CAN/CGSB-3.23-2020 | Aviation Turbine Fuel (Grades JET A and JET A-1) |

| JIG Bulletin 150 | Testing Water Separation Properties of Jet Fuel |

Details

| Measurement Range | 50-100 Water Separation Index (WSI) |

|---|---|

| Temperature Range | 18 °C to 29 °C |

| Sample Size | 220 ml ±10 ml |

| Power | Universal, AC 85-264 VAC 50/60 Hz |

| Outputs | USB, Digital Display, FAT Compatible Files |

| Size (HxWxD) | 38 x 31 x 35 cm |

| Weight | 8 kg |

| CCCN Code | Tariff 90268020 |

Methods

Industries

Spares and accessories for Water Separation Instrument- WSI Analyser - SA9000-0

WSI Replacement Filters (pack of 50) - SA9001-008

View accessory

WSI Water Injector Cleaning Kit - SA9009-001

View accessory

WSI Particulate Filter Replacement Kit - SA9001-003

View accessory

Beaker Kit (pack of 10) - SA9001-002

View accessory

WSI Pre-assembled Filter Kit (pack of 10) - SA9001-001

View accessory

WSI Annual Service Kit - SA9009-0

View accessory

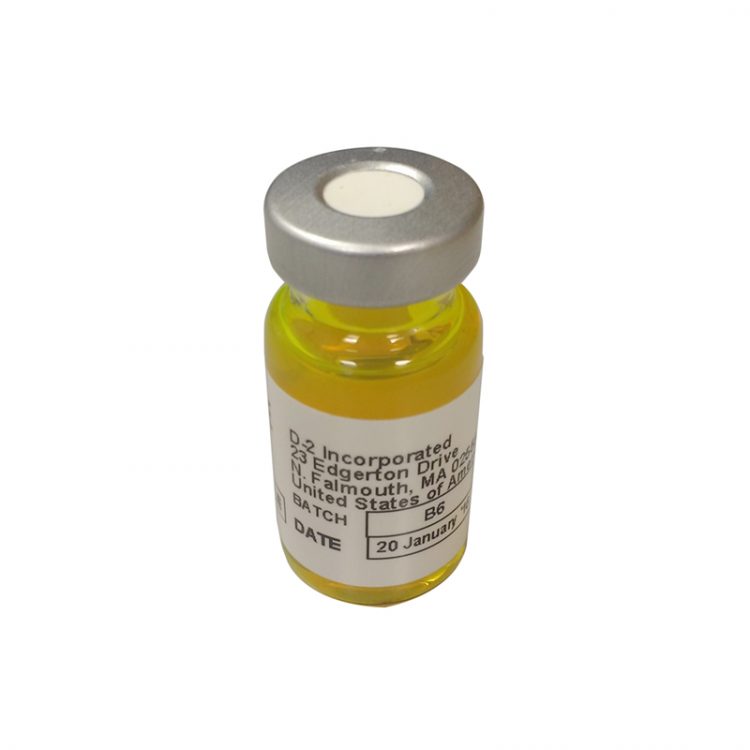

WSI Dye-Water Bottle Pack - SA9001-004

View accessory

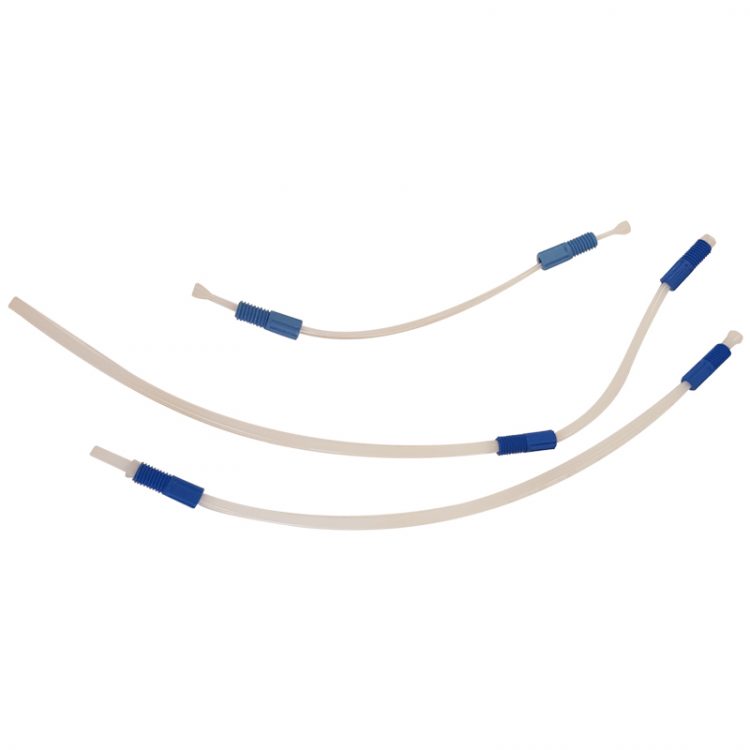

WSI Analyser Connector Kit - SA9006-0

View accessory

Disposable Tips (pack of 192) - 83748-2

View accessory

Pipette 50 to 250 µl - 83747-2

View accessory

Analytical Balance - 99100-2

View product

Thermometer: Precision Plus Digital - 30008-0

View accessory

WSI Dispersing Agent (10 ml) - SA9005-0

View accessory

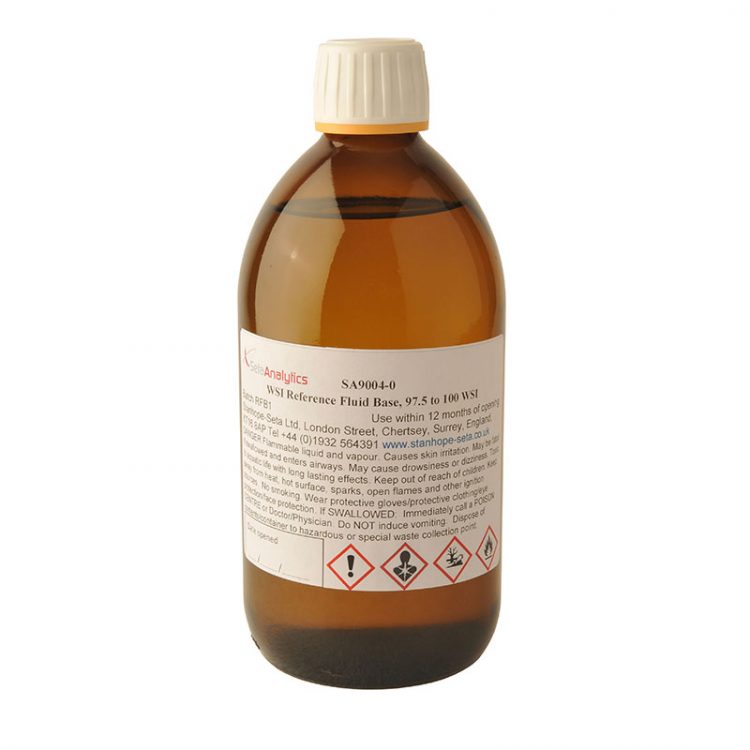

WSI Reference Material Fluid Base - SA9004-0

View accessoryDownload product profile

To view our full range of products, download our latest Product Profile here.

Want to know more?

View our full range of products, or simply get in contact with us for more information.