Why measure water separation?

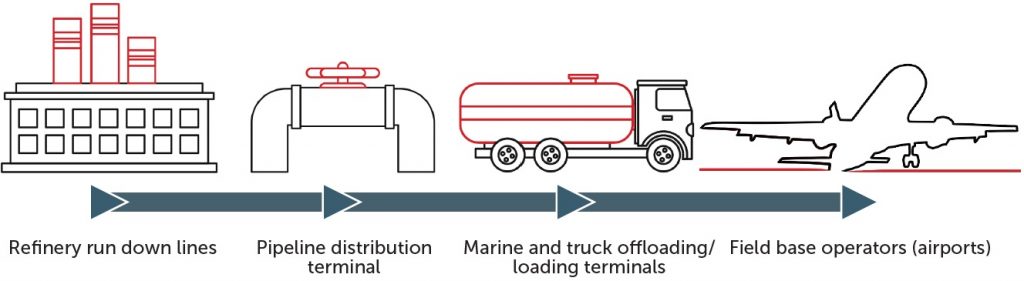

- For fuel quality assurance throughout the supply chain

Why is water removal so important?

- Water provides an environment for bugs to grow, resulting biomass can block filters

- When water forms ice it can restrict fuel flow

- Particulates can cause excessive wear in sensitive fuel system components or block protective filters

Water coalescence

- Water molecules are termed ‘polar’ because they have positive and negative charges that join up with each other

- In a storage tank, dispersed water droplets bump into each other and coalesce

- The coalescence process forms larger droplets that settle to the bottom of the tank and can be drained off

- Coalescing filters can speed up this process

Surfactants

- Surfactants or ‘surface active agents’ are soap or detergent like compounds

- They can be introduced from refinery processes, pipeline or truck cross contamination

- They can coat water droplets or the polar fibres in coalescer elements and make them look non-polar

- The results is droplets don’t coalesce with other droplets and coalescer elements are ‘disarmed’

- Water droplets stay in the fuel stream

How does the Water Separation Instrument (WSI) SA9000-0 help?

- The WSI rapidly and precisely measures the presence of surfactants

- This helps to predict jet fuel coalescence failure and therefore water separation

- The latest Product Quality Bulletin (No 142) from JIG revises the Protocol for Water Separation Testing Downstream of Point of Manufacture and now advises testing can be done using ASTM D8073 (IP 624)

Visit the SA9000-0 Water Separation Instrument product page

Download the WSI Market Guide PDF