ASTM D1655 specifies ASTM D7236/IP 534

ASTM D1655 Standard Specification for Aviation Turbine Fuels now includes ASTM D7236/IP 534 Test Method for Flash Point by Small Scale Closed Cup Tester (Ramp Method) as an alternative to ASTM D93 Pensky-Martens, ASTM D56 Tag and IP 170 Abel

The Small Scale test method and the uniquely approved Setaflash Tester have been in use for over 30 years, primarily for a 1 minute test with 2 ml of sample to carry out a flash no-flash test and more recently for automatic flash point determinations.

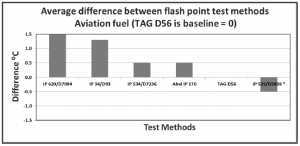

A joint Energy Institute / ASTM Multi-method study has lead to the Setaflash Ramp methods ASTM D7236 and IP 534 being approved for use in ASTM D1655 due to their very close agreement with existing approved flash point methods D56 (Tag), D93 (Pensky-Martens) and IP 170 (Abel). The Setaflash ramp has the best precision of all the flash point methods, thanks to its simplicity and ease of use.

A joint Energy Institute / ASTM Multi-method study has lead to the Setaflash Ramp methods ASTM D7236 and IP 534 being approved for use in ASTM D1655 due to their very close agreement with existing approved flash point methods D56 (Tag), D93 (Pensky-Martens) and IP 170 (Abel). The Setaflash ramp has the best precision of all the flash point methods, thanks to its simplicity and ease of use.

Why choose Setaflash Small Scale?

Many flash point test methods require a complex procedure and large sample volume, meaning testing is likely to take a long time to perform, may require a skilled operator with specialist training and involves greater waste.

Setaflash overcomes these problems, the full Setaflash Small Scale range can be viewed here >

Setaflash overcomes these problems, the full Setaflash Small Scale range can be viewed here >

- Low cost – Setaflash models are low cost and require minimum maintenance

- Multiple models – there are a number of Setaflash models available, catering for a range of applications

- Ease of operation – Setaflash Small Scale flash point testers offer the simplest means of testing and require minimal operator experience to achieve a reliable result

- Automated instrument options – the Setaflash range includes fully automated flash point testers, allowing laboratory technicians to run several instruments simultaneously if required

- Speed of test – Setaflash Small Scale tests take less than 2 minutes to perform compared to the Pensky-Martens test which typically takes 20 minutes or the Abel and Tag which takes over 30 minutes. This is especially important where a large number of samples are to be tested and throughput is vital in supporting efficient laboratory operations

- Small sample volume – just 2 ml of sample is required, minimising the risks associated with potentially harmful fumes whilst virtually eliminating product wasteage and disposal costs, by comparison ASTM D93 Pensky-Martens requires a much larger volume of 75 ml

- Speed of cooling – due to its small cup volume, the cool down period for Setaflash Small Scale tests is much faster than Pensky-Martens

- Portable and lightweight – Setaflash Series 3 models weigh less than 3.5 kgs, can be powered by battery and easily carried to the sample. This is not practical for most other types of flash point tester

- Storage of test results – Setaflash testers have integral data storage memory helping to eliminate operator transcription errors, results can be transferred by USB

Setaflash Small Scale instruments are inexpensive and designed to simplify and speed up the measurement of flash point, making them an affordable and safe procedure for most user applications. Flash point tests need no longer be a costly and lengthy process or one that needs to involve a specialist laboratory.

Choose your Setaflash Small Scale flash point tester >