ASTM D1655 Revision Confirms: Flash Point Correlation Is Not Allowed — What This Means for Aviation Fuel Testing

ASTM International has passed a major concurrent ballot revising ASTM D1655 — Specification for Aviation Turbine Fuels, reinforcing a critical principle long recognised by flash point specialists:

- Flash point test methods cannot be correlated. Each method is an empirical test and valid only when performed using the apparatus defined in that test method and following that test method. For example, a D56 TAG flash point test is only valid when using a TAG apparatus and following D56

This update formally prohibits the use of correlated flash point results and directs users to adhere strictly to the defined methodology and apparatus. This strengthening of ASTM D1655 is especially important for aviation fuels, where flash point is a safety-critical parameter and forms part of the Certificate of Analysis (CoA) and Certificate of Quality.

Why This Revision Was Needed

1. Flash Point Tests Are Empirical — They Cannot Be “Converted” or “Correlated”

Every flash point method, TAG (D56), Pensky-Martens (D93), Abel (IP 170), Setaflash (D3828/D7236), MCCCFP (D7094) is empirical, meaning:

- The value measured is a function of the test method and apparatus design itself

- No test method exists that can “represent” another by mathematical conversion

- Flash point relationships vary only within controlled interlaboratory studies and cannot be generalised for field use

ASTM, the Energy Institute and industry in general have warned for years that using correlated results risks incorrect product certification, especially for aviation turbine fuels.

2. Some Manufacturers Have Built Correlations Into Their Instruments

A small number of instrument manufacturers implemented automatic conversions, for example, presenting a D56 equivalent result from a different apparatus (not TAG), following a different procedure from D56. To further confuse operators, they labelled the result as D56 which is completely incorrect use of the ASTM designation.

This created a serious risk: Labs could unknowingly report a flash point value that was not produced by the specified referee method, potentially leading to an incorrect CoA.

3. The Jet Fuel Multimethod Study (MMS) Provided the Evidence

The MMS, run jointly by ASTM D02.J and the Energy Institute, generated robust statistical relationships between methods. The data showed:

- Each method and sample had its own precision behaviour and relationship to the referee test

- Relationships between methods are small but real (for example, D7236 is typically 0.5 °C higher than D56)

- Correlations are unsuitable for certification, even though comparative relationships are informative for specification development

What the ASTM D1655 Revision Says

1. Footnote K — Updated to Explicitly State: Correlation Is Not Allowed

New wording adds: “Correlated flash point test results are not allowed.”

2. Section 11.1.3 — Use Only the Apparatus Specified by Each Method

The revised text states: “Use only the apparatus specified by each test method. Some apparatus have automated correlation of test results to other flash point methods. These correlated results are not valid and are not permitted for use in this specification.”

This means:

- If you perform TAG D56, you must use a TAG closed cup tester

- If you perform Abel IP 170, you must use an Abel apparatus

- If you perform Setaflash D7236 or D3828, you must use a Setaflash small-scale closed cup tester

- If you use MCCCFP D7094, you must use a modified continuously closed cup apparatus

- If you use Penksy-Martens D93, you must use a Pensky-Martens flash point tester

No test method is allowed to output another test method’s flash point result.

How This Affects Aviation Fuel Testing and Compliance

1. Clearer Guidance for Laboratories

The revision removes ambiguity, any correlated or converted flash point value is invalid for:

- Certification of analysis (CoA)

- Quality release documentation

- Specification compliance

2. Stronger Quality Control

This prevents inadvertent misreporting and promotes international consistency.

3. Supports Ongoing Harmonisation Between D1655 and DEF STAN 91-091

The MMS demonstrated close relationships between methods used globally, and the ballot maintains alignment between ASTM and EI/ISO best practices

Setaflash Methods: Strong Precision and Closest Agreement With Referee Methods

1. Setaflash D7236 Shows Excellent Precision on Jet Fuel

D7236 has the best repeatability and reproducibility of all flash point test methods and aligns closely with the referee methods.

2. Setaflash Results Are Closer to TAG D56 and Abel IP 170 than Other Alternatives

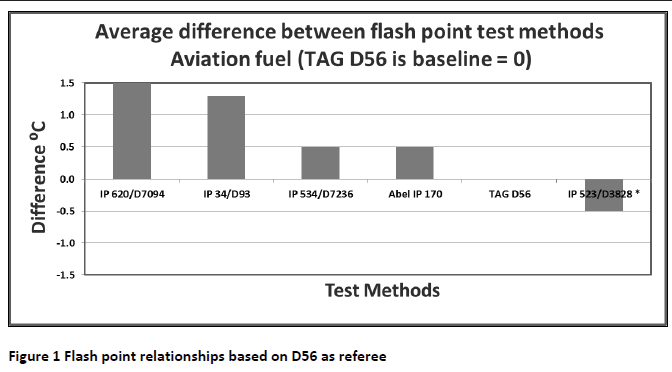

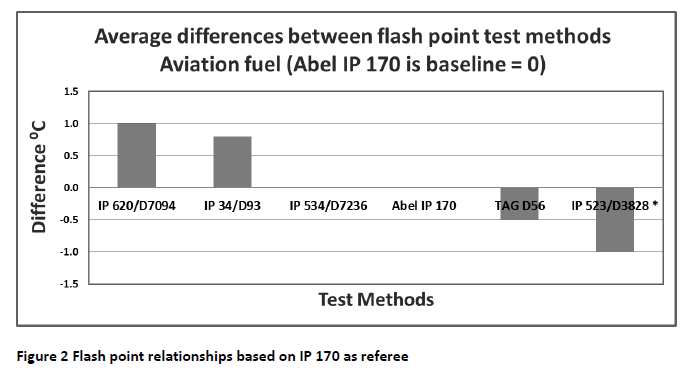

The MMS graphs (Figures 1 & 2) show:

- D7236 results lie very close to D56 (TAG) and IP 170 (Abel)

- D3828 tracks the referee closely

This makes Setaflash particularly suitable for aviation fuels.

3. Industry-Recognised, Standardised and Included in D1655

The revised Table 1 now lists D7094 alongside D56, D93, IP 170, D3828 and D7236 as approved flash point methods.

Why Setaflash Is the Smart Choice for Aviation Fuel Laboratories

- High precision: Supported by MMS testing across 35 laboratories worldwide

- Results track referee methods (D56 & IP 170) more closely than other alternatives: Reduces risk of false failures or borderline results

- Fast, simple operation with small sample volume: Ideal for refineries, terminals and independent test labs

- Fully compliant with the revised ASTM D1655, no correlations, no conversions: Setaflash instruments report direct, valid, specification compliant flash point values

- Lowest entry cost of any flash point tester

Conclusion

The revised ASTM D1655 sends a clear message:

Only true, directly measured flash point results are permitted for aviation fuel certification. Correlated results are prohibited.

This strengthens global fuel quality practice and protects the integrity of CoA reporting.

For laboratories looking for compliant, precise and efficient flash point determination, especially in aviation fuels, the Setaflash (ASTM D7236 & ASTM D3828) methods offer:

- Industry-leading precision

- The closest agreement with TAG and Abel referee methods

- Rapid, robust and fully standard compliant testing

Stanhope-Seta welcomes these changes, which reinforce the importance of industry best practices, correct methodology and highlight the value of high quality, fully compliant apparatus and results.