Stanhope-Seta’s In-line Fuel Conductivity Sensor helps to provide significant operational benefits and cost savings

Static charges can accumulate in low conductivity materials and may discharge in the form of a spark. Distillate fuels have a very low conductivity, approximately 1 million times lower than that of water. As fuel is pumped at high rates through distribution systems, it can accumulate static charge, resulting in a potential fire or explosion hazard.

Static charges can accumulate in low conductivity materials and may discharge in the form of a spark. Distillate fuels have a very low conductivity, approximately 1 million times lower than that of water. As fuel is pumped at high rates through distribution systems, it can accumulate static charge, resulting in a potential fire or explosion hazard.

To reduce the safety risk, minimum conductivity specifications have been set for certain fuel handling operations. SDA, Static Dissipative Additives are injected into the fuel to raise its conductivity to a safe level and ensure it meets the minimum conductivity specifications.

The In-line Fuel Conductivity Sensor fully complies with ASTM D2624: Standard test method for electrical conductivity of aviation and distillate fuels and is mandated in the following specifications

- ASTM D1655: Standard specification for aviation turbine fuels

- DEFSTAN 91-91: Defence standard turbine fule, aviation kerosene jet A-1; NATO F-36

- ASTM D975: Standard specification for diesel fuel oils

- IP 274: Determination of electrical conductivity of aviation and distillate fuels

Traditional fuel conductivity was measured using a Direct Current (DC) based electrical sensor dipped into a fuel sample.

- Requires the fluid to be absolutely still, no movement

- “3 seconds and read” operation

- Highly dependent on temperature

These factors give for significant measurement errors, poor precision and repeatability. DC sensors can only provide manual, handheld test data.

User benefits of the In-line Fuel Conductivity Sensor

- Fully automated direct conductivity measurement in the product line every two seconds

- High precision in-line conductivity measurement accurately manages the SDA additive injection rate

- Automatically provides a permanent record of fuel conductivity

- Suitable for use in hazardous environments (ATEX/FM/FMc/IECEx) approved

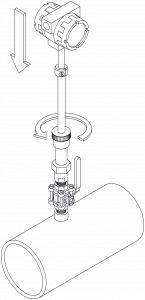

- Easily installed and removed without the need to drain down the line

- Robust stainless steel construction

- Low maintenance: in field annual calibration

Read how Stanhope-Seta’s conductivity sensors saved a refinery $100k per annum

Visit the 99500-0 In-line Conductivity Sensor product page

Download the In-line Conductivity Market Guide PDF