Why measure the flash point of lubricants?

- To detect potential product contamination and identify if the lubricant remains within safe operational specifications

- A flash point significantly lower than usual will be suspected of contamination with a volatile product

- To determine transportation and storage temperature requirements

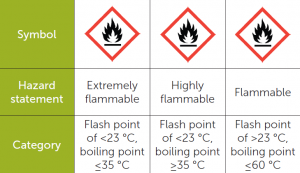

- Lubricants with a flash point of less than 23 °C will require special precautions for safe handling

- This is communicated through the Classification, Labelling and Packaging Regulation (CLP) in Europe and the United Nations Globally Harmonised System (GHS) worldwide

- When combined with tests such as viscosity, viscosity index and specific gravity, flash point can provide information about the quality of the crude oil from which the lubricant was derived as well as the quality of the refining process

What are the implications of lubricant contamination?

- As an example, a report issued by the Marine Loss Prevention Board involved a Bulk Carrier vessel which operated for more than 1 year with the engine lubrication oil contaminated by fuel entering the crankcase due to improperly serviced components

- Minimal lubricant checks resulted in excessive wear to the main engine, crankpin, crosshead and camshaft bearings, plus damage and wear to other lubricated parts of the engine

- The vessel remained off-hire for 6 months whilst repairs were undertaken with a loss of revenue claim to the insurers of $5,000,000

Test methods

- The Setaflash Small Scale test method is specified and approved in many lubricant specifications

- ISO 3679 Determination of flash point. Rapid equilibrium closed cup method

- ASTM D3828 Standard test methods for flash point by small scale closed tester

How does Setaflash help?

- A portable, lightweight, compact instrument, tests can be carried out on-site

- Setaflash requires just 2 ml of sample and a test takes under 2 minutes, reducing waste

- Results assist those responsible for analysis of in-service lubricant properties and also provide a strategic expection test used to confirm and diagnose occasional non-conforming conditions that can be flagged by routine tests

See our range of Setaflash flash point testers

Download the Flash Point: Lubricants PDF