Flash point is the lowest temperature at which vapours from a sample combine with air to give a flammable mixture and ‘flash’ when an ignition source is applied.

The test

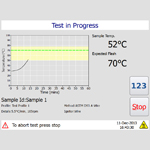

A sample of specified volume is introduced to the test cup which is maintained at the test temperature. After a specified time, a test flame is applied and the presence or absence of a flash observed.

Atmospheric pressure can also affect the result, as a low barometric pressure will cause any flammable vapours to be present at a lower temperature whereas a high atmospheric pressure will delay the presence of flammable vapours until a higher test temperature is reached.

Why test for flash point?

Flash point testing has been an established practice for more than 100 years to help assess and classify the safety hazard of a material for classification, storage and transportation purposes and is used by industries as diverse as the petrochemical, waste and cosmetics industries.

The fundamental reason for measuring flash point is to enable specific and correct precautions to be taken when manufacturing, storing, transporting or using liquids.

There are three main flammability categories:

- Extremely flammable: Flash point below 0° C

- Highly flammable: Flash point below 21 °C

- Flammable: Flash point below 55 °C

A change in flash point may indicate the presence of potentially hazardous volatile materials or the adulteration of one product by another. For example, pure Ethylene Glycol has a flash point of 111 °C, but with just 2% of Acetaldehyde present, the flash point becomes 29 °C. Similarly, a difference in flash point may indicate that a sample has been adulterated. Petroleum spirit added to engine oil will reduce the flash point.

Reliable and precise measurement of flash point requires the conditions of testing to be standardised as over 20 parameters can affect the flash point of a sample. This includes the test cup and lid dimensions, the temperature and position of the ignitor, the dipping sequence and frequency, as well as the test time, heating rate, atmospheric pressure and many others.

Mandatory international and national regulations are set by bodies such as the UN, IATA, EPA, EU and Health and Safety executives. The following are the most known international regulations, that include the rules for flash point testing, are applied for classification into the correct hazard group:

- CLP Classification, Labelling and Packaging

- ADR Carriage of Dangerous Goods by Road

Waste disposal regulations

EU guidelines and Hazardous Waste Regulations require rapid hazard classification of a sample (liquids, used oils and solids) before it can be disposed of.

“For us, the Setaflash Tester is a valuable piece of kit and we’d struggle without it. Our main use is to detect whether a waste is hazardous or not, as this can have knock on effects in terms of cost, safety, compliance and potential processing routes.” Nick Richardson, Laboratory Supervisor, Castle Environmental